Back

Back

September 28, 2023

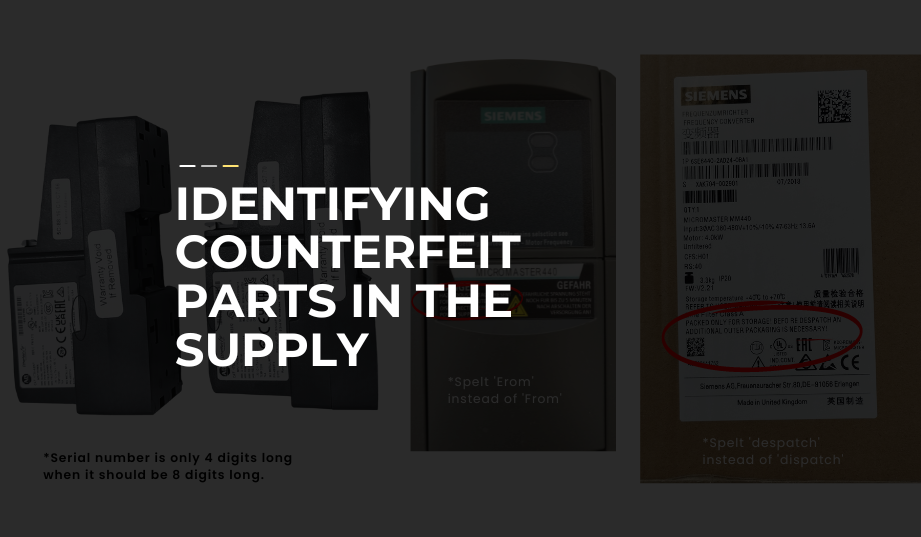

Identifying Counterfeit Parts

Counterfeit components extend beyond being mere inexpensive replicas. They present substantial hazards to the intricate manufacturing process, which hinges on the harmonious collaboration of an array of automated industrial parts. These substandard elements carry the potential to trigger numerous malfunctions, capable of bringing production to a standstill, jeopardising the well-being of employees, and resulting in substantial financial losses due to repairs and missed sales.

In light of this, what proactive measures can be taken to safeguard your production process?

Our Warehouse Specialist in Quality Assessment has over five years of experience in counterfeiting procedures, he goes on to say, “All industrial parts that come across my desk undergo rigorous tests to ensure that all parts supplied to the Obso clientele are genuine. Here are some of the preventative measures I’ve employed to stop over 215 fake parts from reaching our clients:”

Source Wisely: Cooperate with reliable vendors who have a history of authenticity and excellence. At Obso, we use a very niche group of suppliers and put them through a rigorous testing process. We also do not make any purchases from China, as we’ve realised that more part imitations are prevalent within that region.

Implement Stringent Verification Procedures: For all incoming parts, set up verification protocols. As a rule of thumb in our onboarding process, all new suppliers who pass through the initial testing phase must complete a supplier agreement and agree to supply only genuine original manufacturer parts. We also include clauses such as limiting them from buying from certain suppliers or parts of the world. And as an additional future-proof reference, any suppliers that send counterfeit goods are automatically entered into our non-conformance report, investigated and blacklisted within our system.

For every part that comes in for repair or replacement, these are some practical ways we perform quality checks:

- All barcoded units are scanned to ensure what is scanned matches what is on the unit.

- Manufacturer labels are checked to ensure the text displayed on the nameplate matches the font of known genuine parts and there are no spelling mistakes.

- Check the casing material is correct.

- Check that the unit weight matches genuine manufacturer parts

Below are some counterfeit units that have been stopped during our quality checks. These examples show common indicators that the goods are not genuine with serial numbers being tampered with and spelling mistakes displayed on the unit.

Educate Your Team: Equip your employees with information about spotting fake parts. The first line of defence is awareness – knowing what to look for and how it can be mitigated.

Keep up-to-date: Keep an eye out for new trends in counterfeiting. Future problems can be avoided by being proactive and remaining one step ahead of the game.

Even though fake industrial automation parts are cunning, you can outsmart them using the appropriate tactics. By guaranteeing the legitimacy and calibre of every component in your supply chain, you are prioritising not just the integrity of your products but also the safety of your employees and the production process as a whole.

test